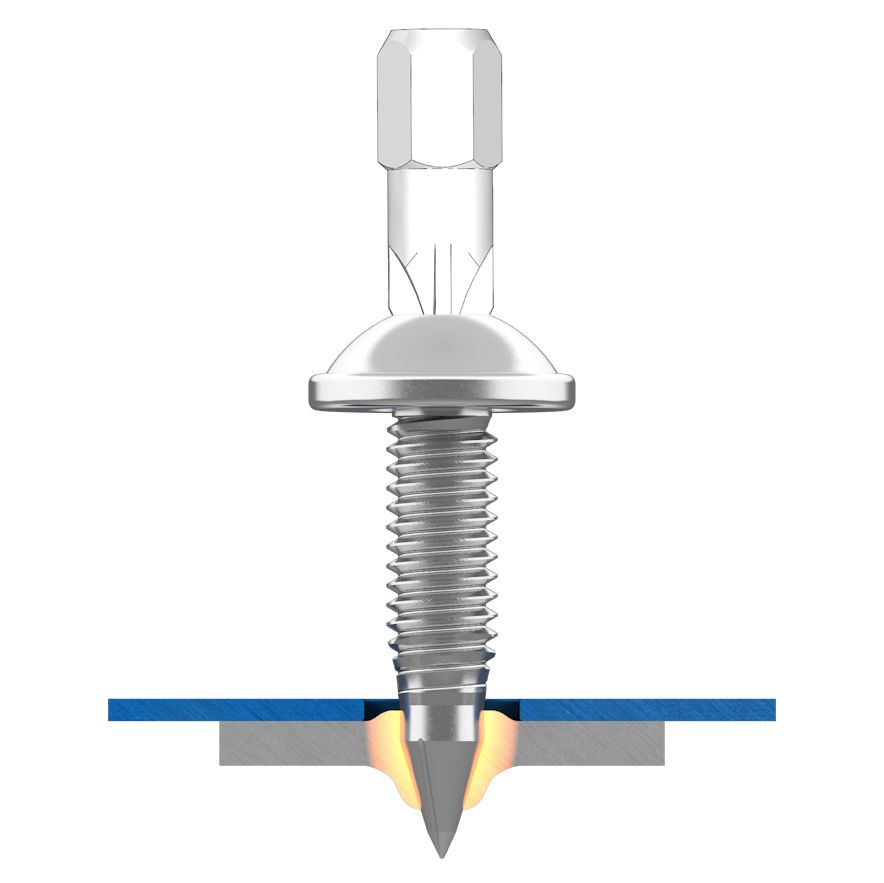

Flow forming screw for sheet metal

For stamped holes, rims and blind holes in steel or alloy sheet metals.

Properties

- For stamped holes, rims and blind holes in steel or alloy sheet metals.

- The flow forming tip heats up and softens the sheet metal momentarily. The forming of the hole and the rim starts in the heated material and the thread forming process follows.

- The betzer pentadrill screw is case hardened and tempered.

Economic advantages

- Economized production sequence by direct mounting without stamping.

- No counternuts or other fasteners required. Reduced number of assembly components.

- Short assembly time when using high-speed screw

- drivers (approx. 3000 rpm).

- Reduced overall weight of the component or subassembly.

Quality features

- The positive fit of the betzer pentadrill screw in the selfformed thread prevents spontaneous loosening.

- Thread forming without chips, no loss of material.

- Low tapping torques.

- High tightening torques are possible.

- Once tightened, the betzer pentadrill screw resists high stripping forces.

Installation advantages

- Use of high-speed screw drivers over 2000 rpm recommended.

- During assembly vertical pressure has to be exerted to heat up the sheet metal.

- The betzer pentadrill screw can be removed and retightened repeatedly.

- Subsequent screw fastening with metric screws possible.

- Especially suitable for automatic assembly.